AMADIVAYISI ESANDLA ESITHUTHWAYO

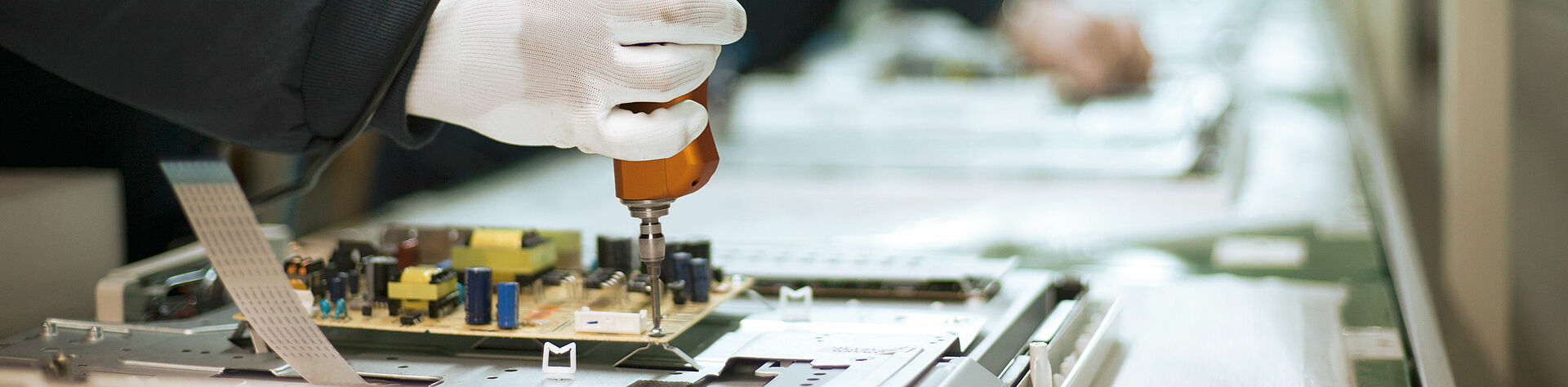

Ulayini ogobile kufanele umiswe ngendlela efanele emzamweni wokuqala - lapho uzidweba, asikho irabha futhi akukho okwesibili.Ngenxa yenjini yokudlidliza ephansi evela ku-HT-GEAR, umshini we-tattoo umile ngokuphelele esandleni futhi ungaqondiswa ngokuqondile.Njengoba kunembe nje ukuqiniswa kwezikulufu ezincane nge-screwdriver enenjini enetorque elinganiswe ngokunembile.Ngamanye amadivaysi afana nama-secateurs noma ama-shears okuthena, amadrayivu e-HT-GEAR ahlinzeka ngamandla adingekayo emahoreni amaningi ngevolumu ephansi kakhulu.

Alikho irobhothi eliseduze nokuguquguquka nokuguquguquka njengesandla somuntu.Kungashiwo okufanayo “ngokulawula” kwayo ngobuchopho nangokwazi.Uma kuziwa ekuguquguqukeni kwezinhlelo zokusebenza ezingase zibe khona, le nhlanganisela imane nje ayinakuhlulwa.Nokho, miningi imisebenzi lapho isandla sidinga khona usizo.Lokhu kuba sobala uma uzama ukuhlanganisa ifenisha enkulu usebenzisa inqwaba yezikulufu ngaphandle kwe-screwdriver kagesi.Imishini ephathwa ngesandla ihloselwe ukusiza kunokuvimba.Lokhu kusho: Isisindo esiphansi kakhulu, ubukhulu obuncane kakhulu, ukudlidliza okuncane nokusebenza okubushelelezi, okuthule.Ezinye izinhlelo zokusebenza zingadinga amandla abalulekile noma amandla asetshenziswa ngokunembe kakhulu.Izikulufu zikagesi kanye nezikere zikagesi zokuthena kumele zilethe amandla aphezulu kusukela ngesikhathi zikhanyiswa bese ziyeka ukunyakaza futhi ngokushesha uma zicishiwe.Izinaliti zomshini we-tattoo zivame ukusetshenziswa okungaguquki amahora amaningi ngesikhathi.Kodwa kubalulekile ukuthi i-handpiece ingashisi.

I-HT-GEAR inikezela ngesixazululo esilungile sedrayivu sazo zonke izinhlobo zamadivayisi aphathwayo.Amandla abo ayisisekelo ayakholisa ngazo zonke izindlela: Ama-micromotor avela ku-HT-GEAR afinyelela amanani aphezulu okusebenza ngamavolumu amancane kakhulu kanye nesisindo esincane.Iphothifoliyo yensiza ebanzi yama-gearheads, amabhuleki, izilawuli, izifaki khodi nezixhumi zemishini iqukethe inhlanganisela efanele yalo lonke uhlelo lokusebenza.

Ukunemba okuphezulu nokuthembeka

Isisindo esincane

Izikhathi zokusebenza ezinde kakhulu